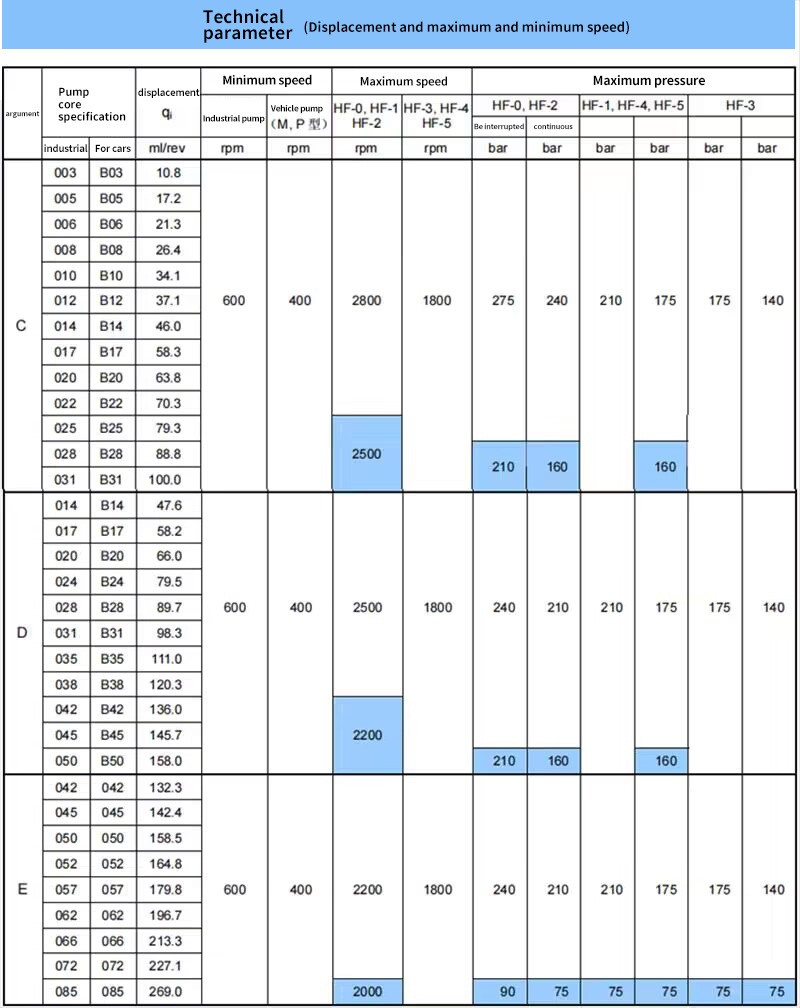

Deplasarea pompei cu o singură paletă seria T6 și viteza maximă și minimă

Note: HF-0, HF-2 = Petroleum-based anti-wear hydraulic oil;

HF-1 = Petroleum-based hydraulic fluid (non-anti-wear);

HF-3 = water-in-oil emulsion;

HF-4 = water glycol;

HF-5 = Synthetic hydraulic fluid (phosphate ester fluid, etc.);

Coupling and spline holes:

1. The equipped coupling spline hole should be able to float and automatically center. If both halves of the coupling are rigidly supported, their misalignment should be within 0.15mm (total difference in dial indicator readings) to reduce wear. The deflection of the central axis of the two halves of the spline holes should not be greater than ±0.05 mm / 25.4 mm;

2. The coupling spline hole must be lubricated with lithium-molybdenum disulfide or similar grease;

3. The coupling must be heat treated, and the heat treatment hardness is: Rc 27~45;

4. The spline hole should be processed according to the level 1 precision specified in SAE-J498b (1971). According to this specification, it should be a flat tooth root and tooth side fit.

Flat key shaft extension:

T6 series vane pumps are designed with high-strength keys, so when installing or replacing this series of pumps, you must use heat-treated high-strength keys to ensure the longest service life. If the flat key needs to be replaced, the heat treatment hardness of the replacement key should be: Rc 27~34, and the edge of the key must be chamfered 0.75~1 x 45° to fit the fillet at the bottom edge of the keyway.

Note: The coaxiality deviation between the pump input shaft and the drive shaft should be within the range specified above for the spline shaft.

Drive shaft radial load:

This series of products was originally designed to be driven by inter-shaft torque, and the transmission shaft cannot bear axial and lateral loads. Please see the relevant dedicated chapters for details.

Initial start-up: During initial start-up, it is best to run at the lowest speed and lowest pressure for a short period of time to make the hydraulic pump meet operating conditions. At this time, if the outlet of the pump is equipped with a relief valve, please loosen it to reduce the pressure to the minimum.

If possible, a bleed point should be provided in the system loop to remove air from the system. Do not allow the pump to operate at high speeds and pressures without checking the initial operating conditions of the pump and venting the oil.

General instructions for use:

1.Check the pump's steering, speed range, pressure, temperature, oil quality and viscosity;

2.Check whether the suction port condition of the pump meets the usage requirements;

3.Check the type of drive shaft and whether the torque meets the working condition requirements;

4.Select an appropriate coupling to minimize the radial load of the pump (caused by weight, non-axial deviation, etc.);

5.Filtration: Must meet the requirements of the minimum pollution level;

6.Working environment: Avoid noise, pollution and impact.